First dreamt up in 1988, the HZMB finally launched on 24 October, 2018. After nine years of construction, the newly opened bridge is transforming leisure and business travel in the Greater Bay Area. Aspects of the project were incredibly challenging – especially when it came to constructing the bridge over the open sea. Here, you will get an insight into how the bridge came into being, the journey from construction to launching as the world’s longest sea crossing, and the design thinking behind it all.

The construction story

Taking the HZMB from concept to reality was a long and complicated process involving governments, architects, engineers and construction workers, among many others. We look at how the project began, and how it evolved over time.

Timeline

1983An idea is born

Gordon Wu floats the idea of building a bridge that would reduce travel time to Macau, and make Guangdong province more accessible. Infrastructure committees explore the options in the 1990s.

2003Task force established

Study commissioned by National Development and Reform Commission and Hong Kong government confirms the need to build a land transport link between Hong Kong and the western Pearl River Delta. Hong Kong-Zhuhai-Macau Bridge Task Force set up.

February, 2008Inter-government discussions

The governments of Hong Kong, Macau and Guangdong agree on a cost-sharing arrangement for the main bridge, with Hong Kong covering 50.2 per cent, Guangdong covering 35.1 per cent, and Macau covering 14.7 per cent.

They also agree to be responsible for the construction, operation and maintenance of their own boundary crossing facilities and associated link roads

2009Design work begins

Preliminary design and site investigation work begins in March. In December, reclamation work begins on the Zhuhai-Macau border crossing facilities.

2010A vision for the main bridge takes shape

The Ministry of Transport approves the preliminary design for the main bridge in March.

In December, the governments sign agreements confirming the design and build direction for the tunnel and artificial islands, and construction begins.

2012Work begins on the Hong Kong Link Road

Consisting of sea viaducts and tunnels, this road will link the main bridge with the Hong Kong Boundary Crossing Facilities (HKBCF).

2013A series of firsts

The first segment of the main bridge’s tunnel tube is immersed in the waters of the Pearl River Delta in early 2013. This is the first step in installing what will become the world’s longest immersed tube tunnel.

In December, the main bridge’s first composite bridge girder is erected.

Work also begins on the Tuen Mun-Chek Lap Kok Link.

September, 2016Over-water construction finishes

Construction of the viaduct sections of the main bridge wraps up.

June, 2017Underground works wrap up

Construction concludes on the tunnel section of the main bridge.

June, 2018Finalising inspections

Handover inspections for the HZMB complete. The bridge is almost ready to go.

October, 2018Hong Kong, Macau and Zhuhai get connected

The HZMB officially opens, and vehicles begin to make the trip between Hong Kong, Zhuhai and Macau.

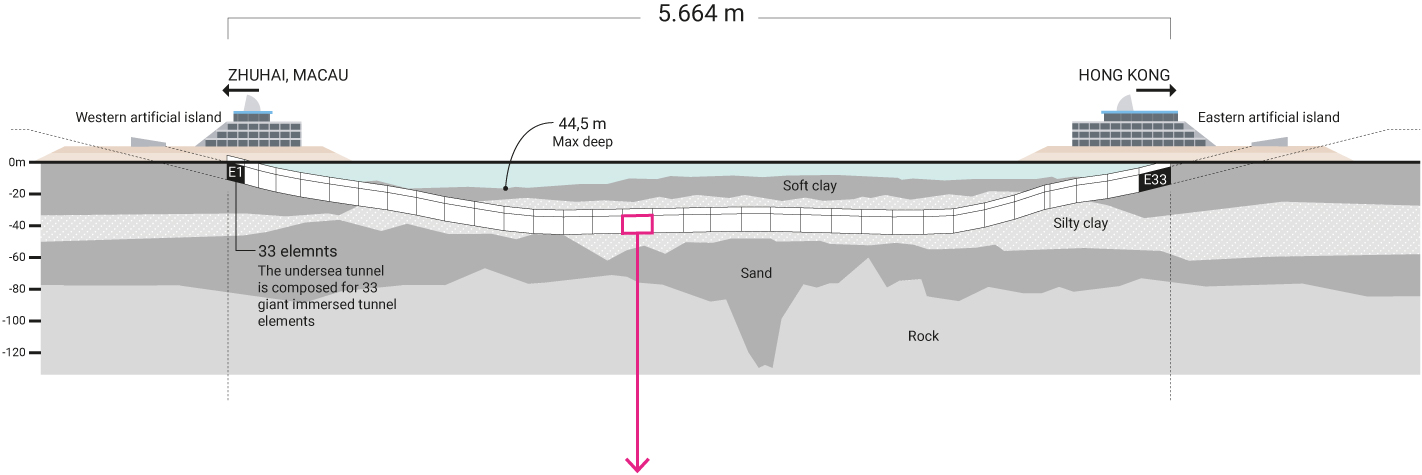

The main bridge consists of elevated bridges 22.9km long and a 6.7km tunnel. It is the longest immersed tube tunnel in the world. Building this part of the HZMB was the most critical and challenging part of the project.

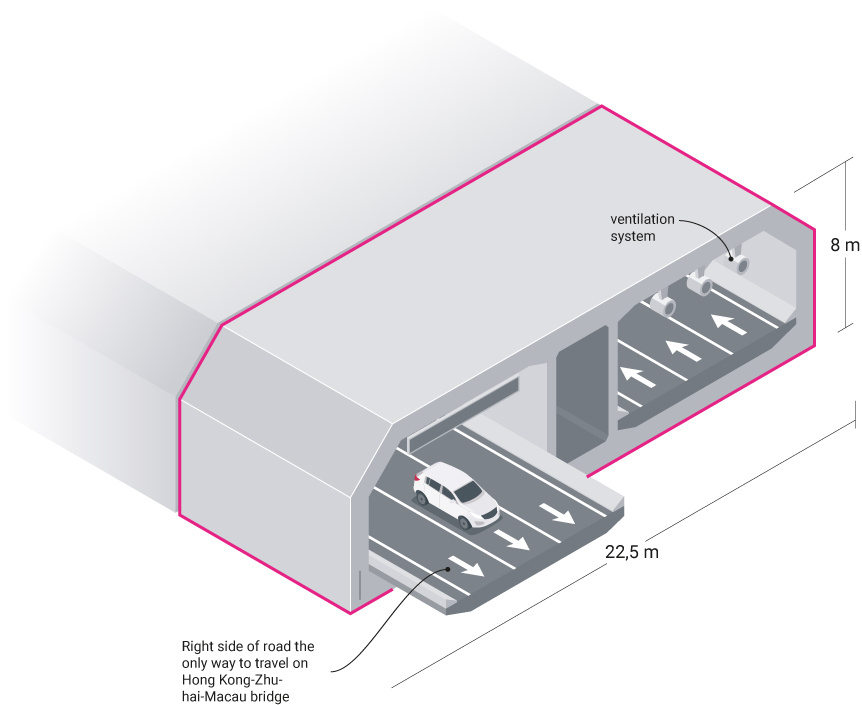

An underwater tunnel was part of the solution to keeping shipping lanes open. The six-lane tunnel consists of 33 segments situated 45m below sea level.

Like many other elements of this project, the tunnel segments were precast elsewhere, in order to minimise disturbance to marine life and shipping lanes. They were then transported to the site by tug boats and placed underwater – no easy task, given technical difficulties such as strong monsoon winds and adverse water currents and wave conditions.

The tunnel is also designed to withstand earthquakes of up to 8.0 on the Richter scale.

The sub-sea tunnel

Making way for marine traffic

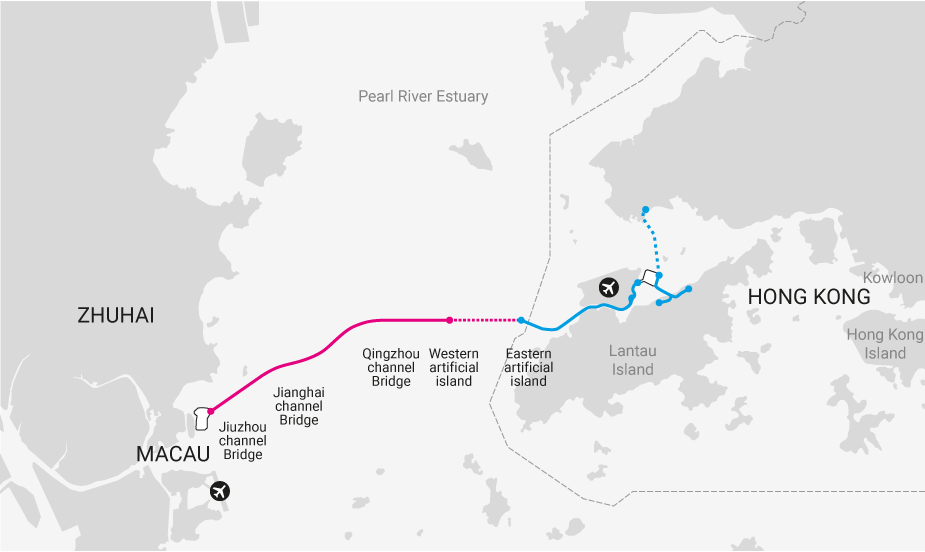

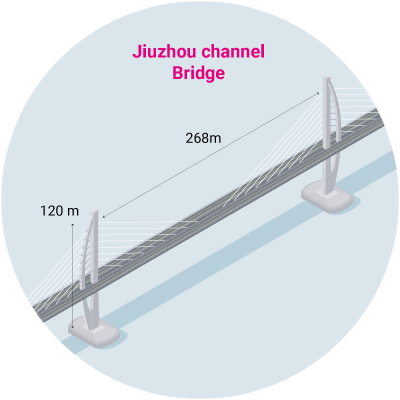

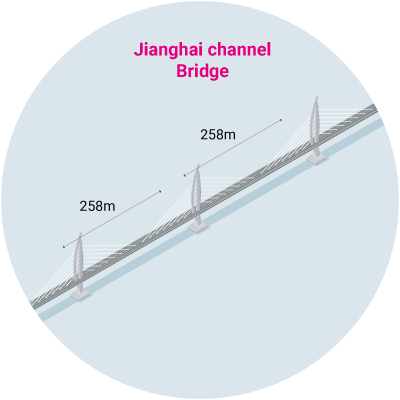

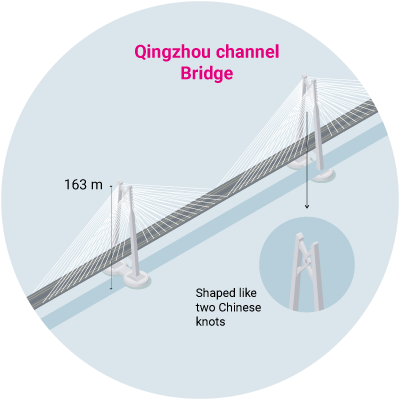

Catering to the busy shipping lanes the HZMB passes through are three large, cable-stayed bridges, which make up the 23km sea viaduct part of the bridge. They are, from west to east, the Jiuzhou Channel Bridge, the Jianghai Channel Bridge and the Qingzhou Channel Bridge. At 458m long, the Qingzhou Channel Bridge is the longest of the three.

Mouse over to see more information

Tap over the buttons

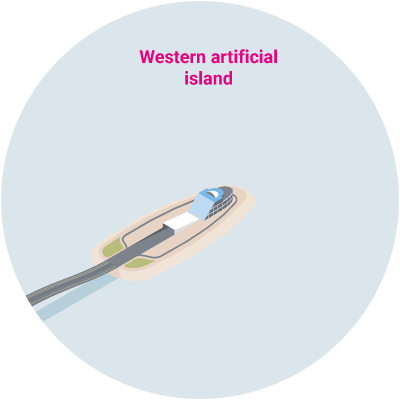

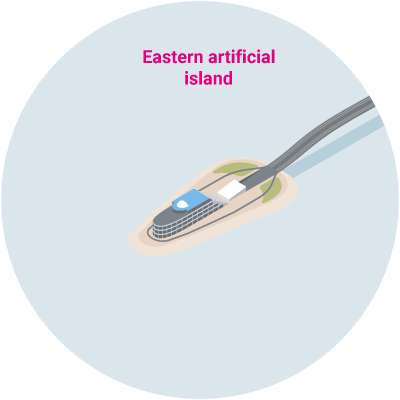

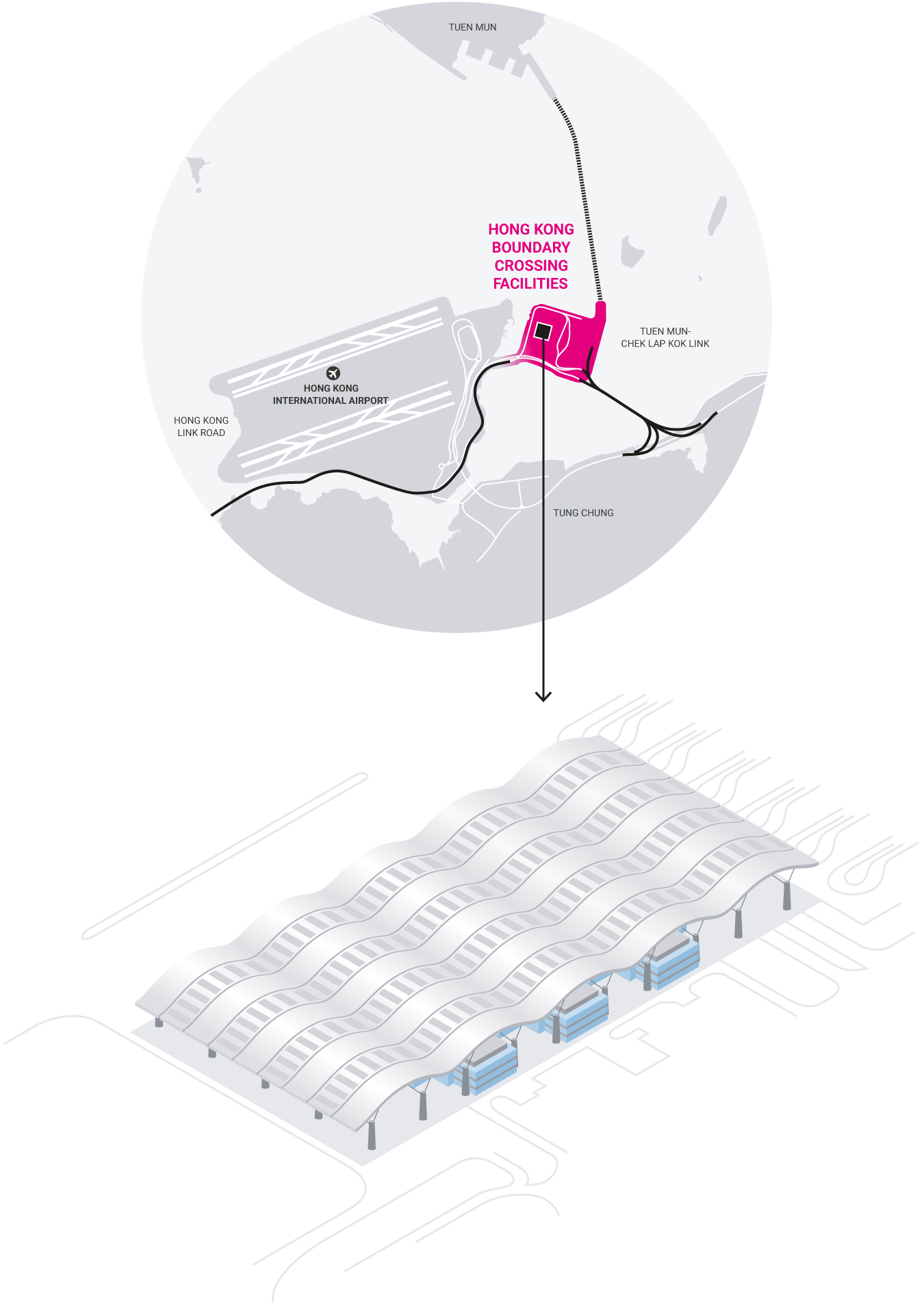

Four artificial islands were purpose-built for the HZMB project; one housing Hong Kong’s boundary crossing facilities, and another home to boundary crossing facilities for Zhuhai and Macau.

Building these artificial islands was challenging, from design, engineering and construction perspectives. The island that houses Hong Kong’s Boundary Crossing Facilities (HKBCF), for example, is 150 hectares in size, and building it required land reclamation works and construction of a seawall more than 6km long.

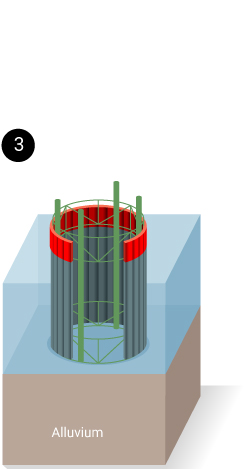

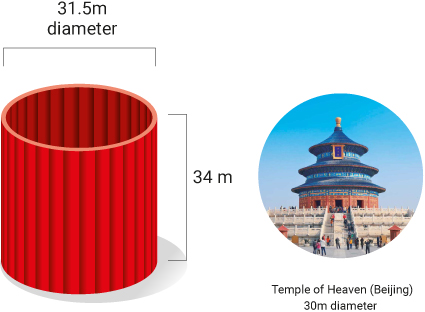

The island sits in the open waters north-east of Hong Kong International Airport, and part of its seawall was made using steel cells installed into the seabed to create a solid foundation, along with rubble mound. The steel cells, or cofferdams, are huge watertight enclosures, each of them 31.5m wide. Some cells were constructed on-site using 200 flat steel plates per cell, and others were prefabricated elsewhere before being towed into position.

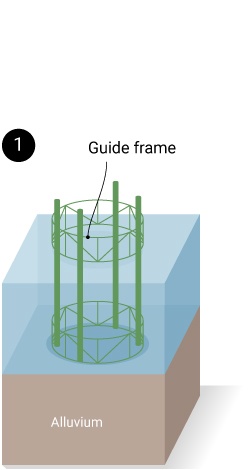

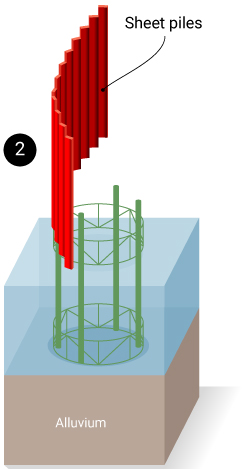

Installing the steel cells on-site

Positioning guide frame

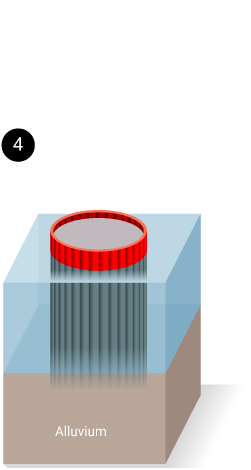

Driving of sheet piles into seabed around guide frame to form the cell

Cells are driving through softer marine deposit down to firmer alluvium

Back filling the cell by public fill

Cells are driving through softer marine deposit down to firmer alluvium

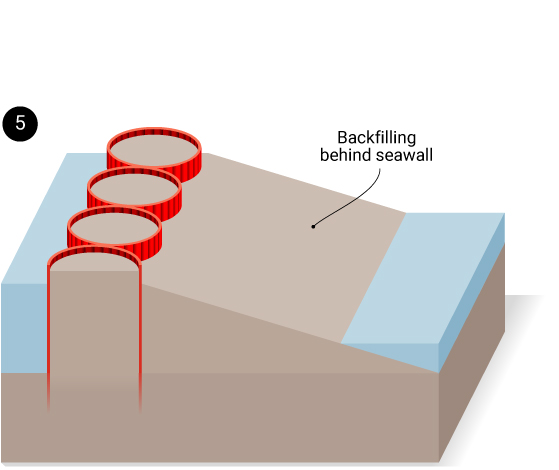

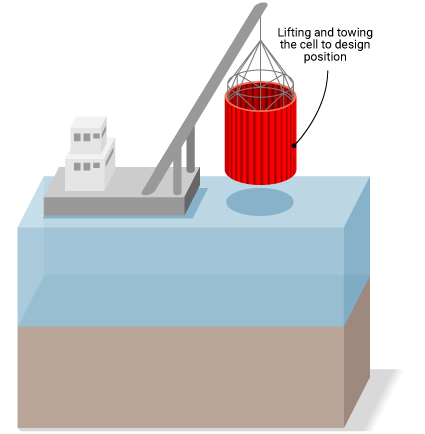

Installing prefabricated steel cells

Sizing up

Comparing the steel cells of the seawall with the Temple of Heaven

Exploring the Hong Kong Boundary Crossing Facilities (HKBCF)

Travellers taking the HZMB to Hong Kong, and from Hong Kong to Macau, Zhuhai and beyond, need to clear immigration at the HKBCF - a new immigration and transportation hub located on an artificial island purpose-built for this task. Passenger and goods clearance facilities are housed in the HKBCF, as well as vehicle inspection facilities and frontline offices for the likes of the Immigration Department.

AECOM worked with Aedas and Rogers Stirk Harbour + Partners on the design for the HKBCF Passenger Clearance Building, creating wide, open spaces that are built for people movement. Striking design features include tree-like supporting columns and deep canyons that run from the lower levels to the roof 30m above, and that allow natural light to reach every floor of the building.

Hong Kong

Boundary Crossing Facilities

Multidisciplinary design, engineering and build firm Arup worked on many aspects of the HZMB, helping make day trips between Hong Kong, Macau and Zhuhai a reality. Among other feasibility, design and infrastructure projects, Arup developed preliminary designs for the main bridge. Arup’s bridges expert, Naeem Hussain, designed the sail-shaped towers that help support the Jiuzhou Bridge.

Courtesy by Arup