Cracking the enigma

In 1974 local farmers in Xian unearthed the 2,000-year-old Terracotta Army. Here we look at how the humble clay was moulded into such fine figures

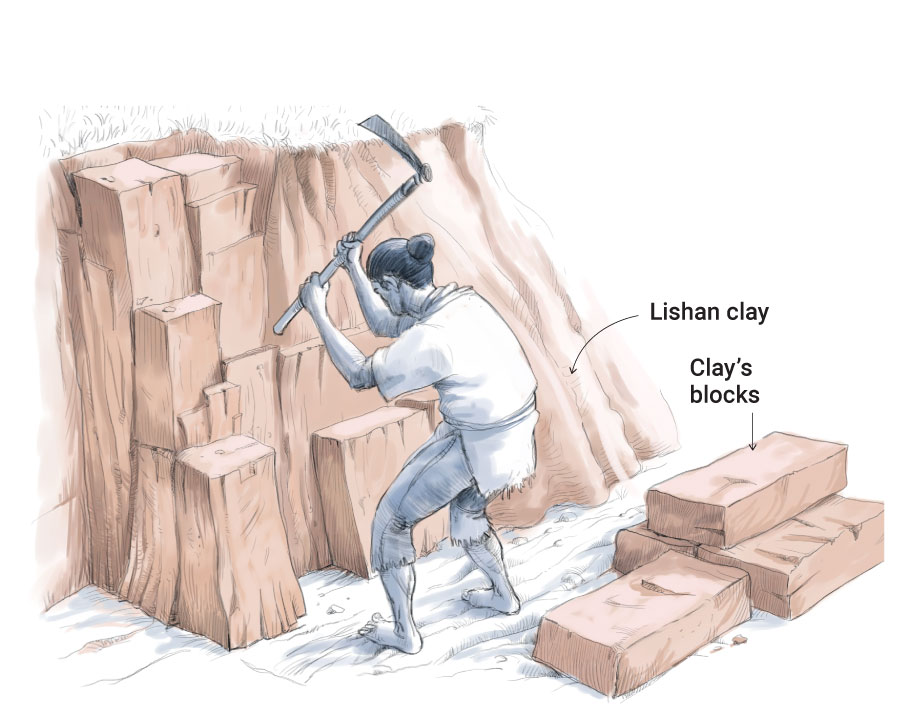

Extraction and preparation of materials

01Thousands of workers were used to extract clay in rough blocks from Lishan

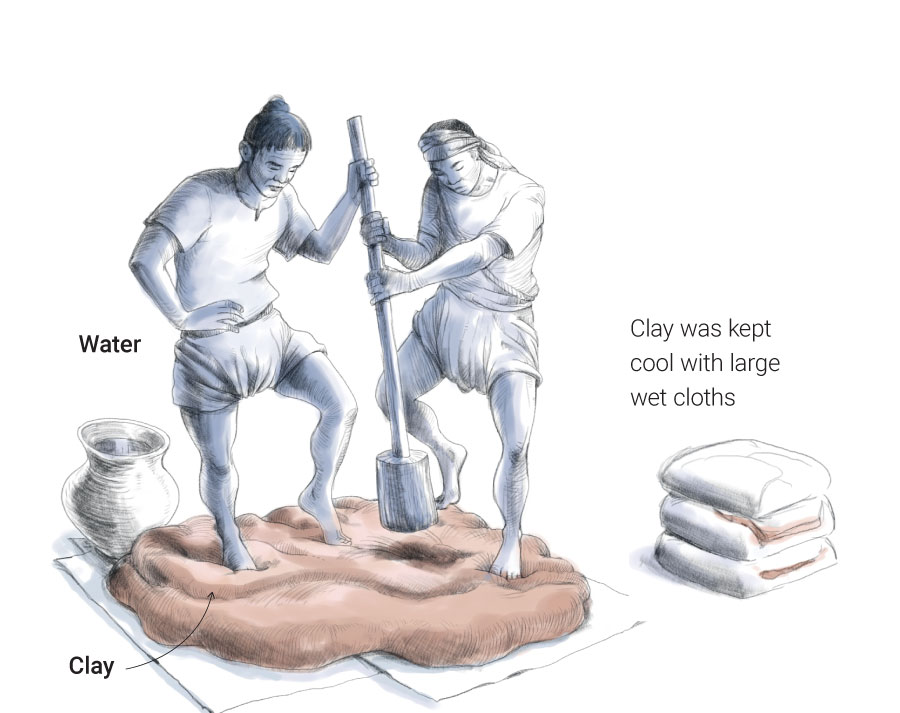

Extraction and preparation of materials

02Blocks were kneaded with water, and mixed with quartz sand, mica and feldspar

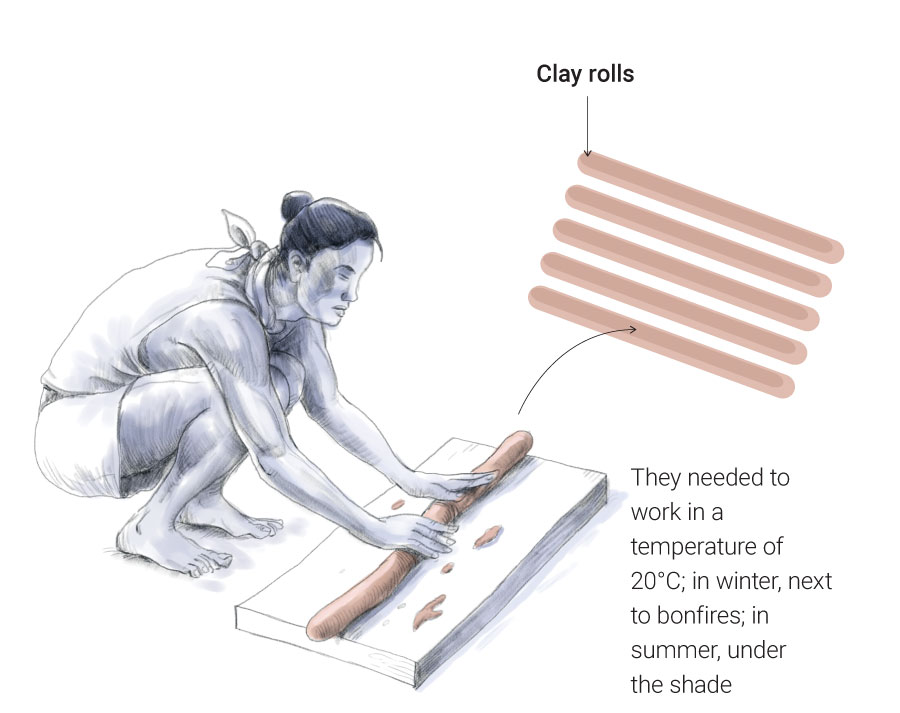

Extraction and preparation of materials

03Craftsmen kneaded the clay into rolls that would be used as moulds for the figures

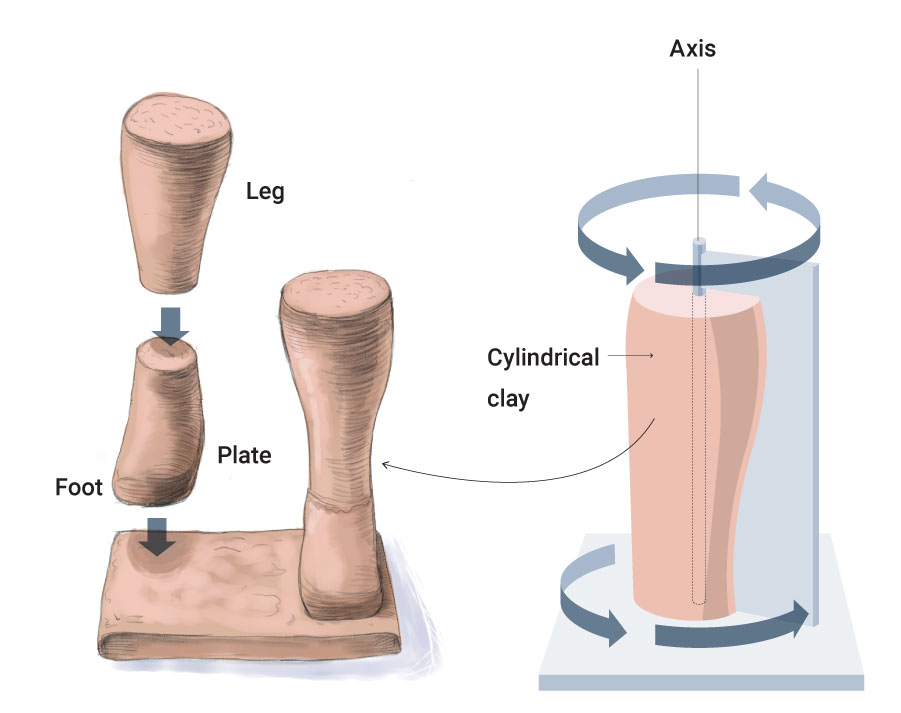

Figure modelling

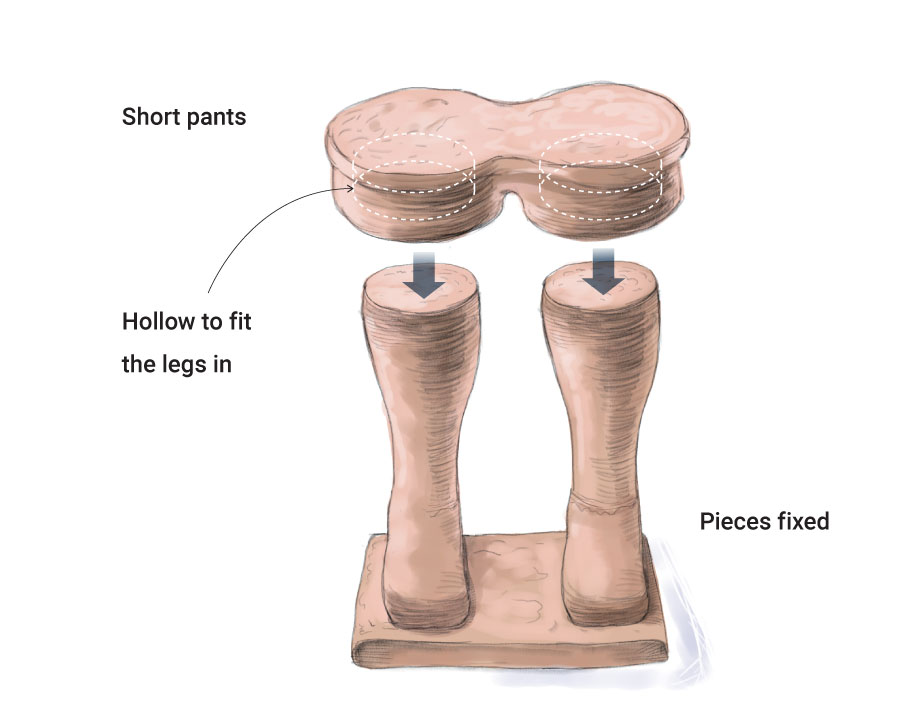

04They started with the base by modelling the legs in different sections, a lathe was used to make prefabricated legs in sections

Figure modelling

05Prefabricated sections of the breeches were added to the legs

Figure modelling

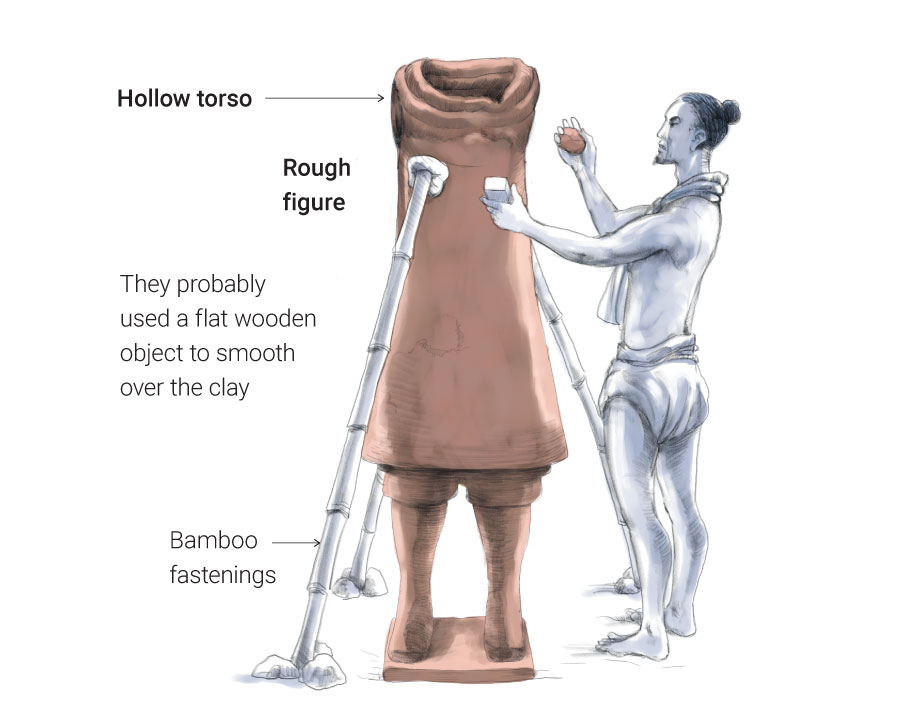

06The rest of the breeches were made by coiling strips of clay upwards. In order to make the clay strips tight and strong, artisans would put a piece of sackcloth inside as an underlay. They would then pound it until the shape and size was right

Figure modelling

07Torsos were roughly shaped by hand. During the moulding, the clay must remain wet to maintain its adhesive quality and plasticity

Figure modelling

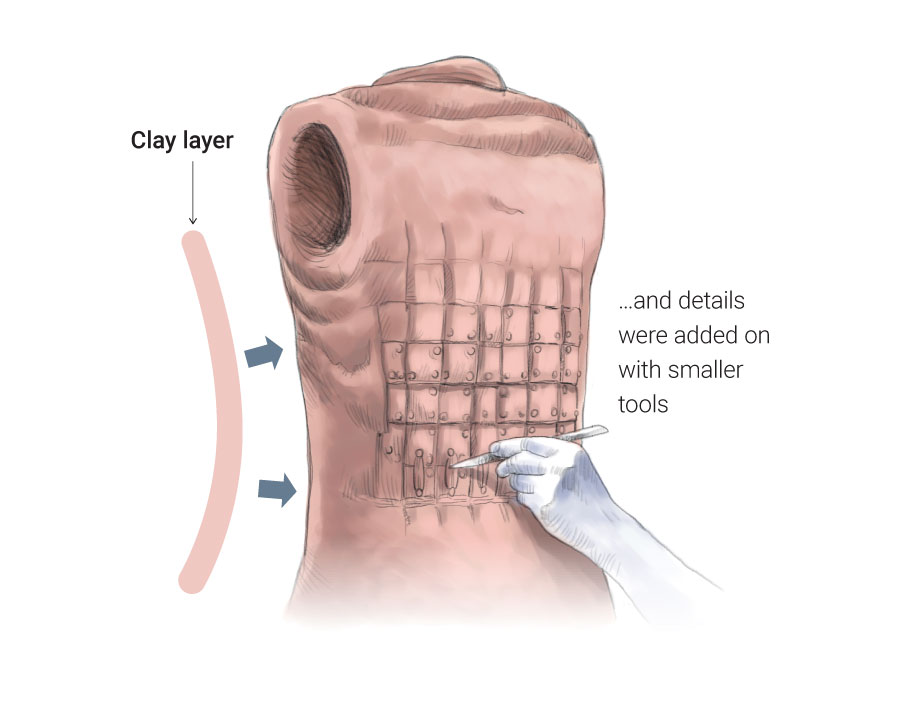

08New clay layers were added over the body…

Figure modelling

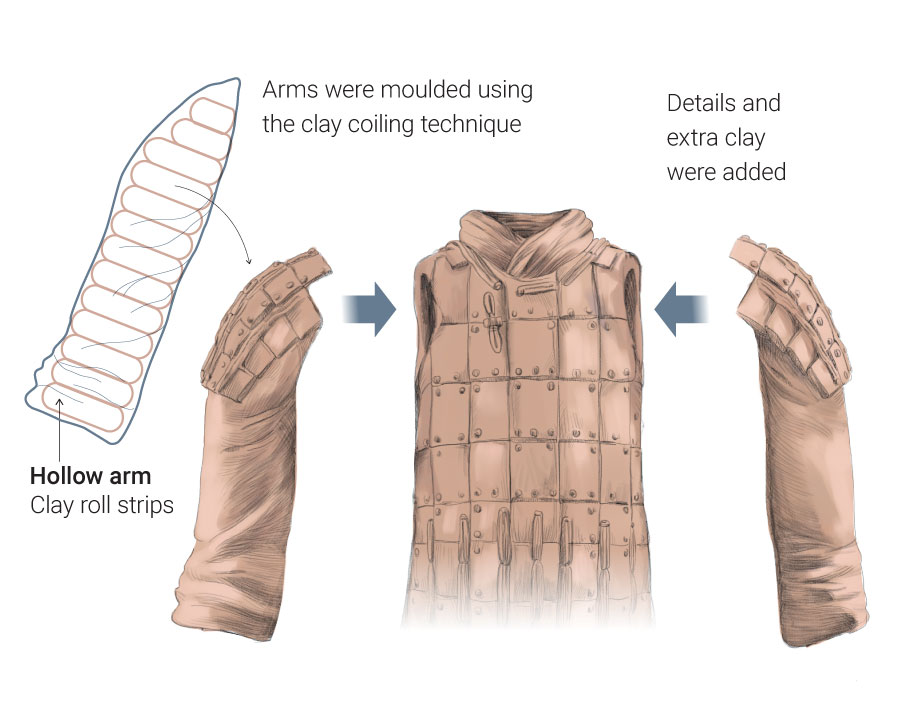

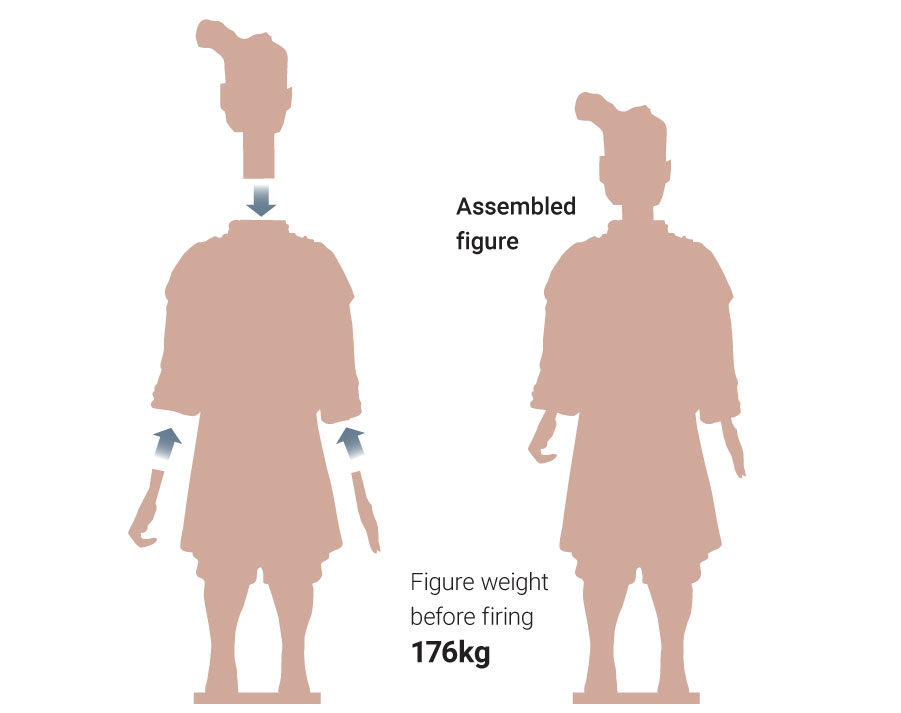

09After the torso had been dried in the shade, artisans would attach the hollow arms to the sockets

Figure modelling

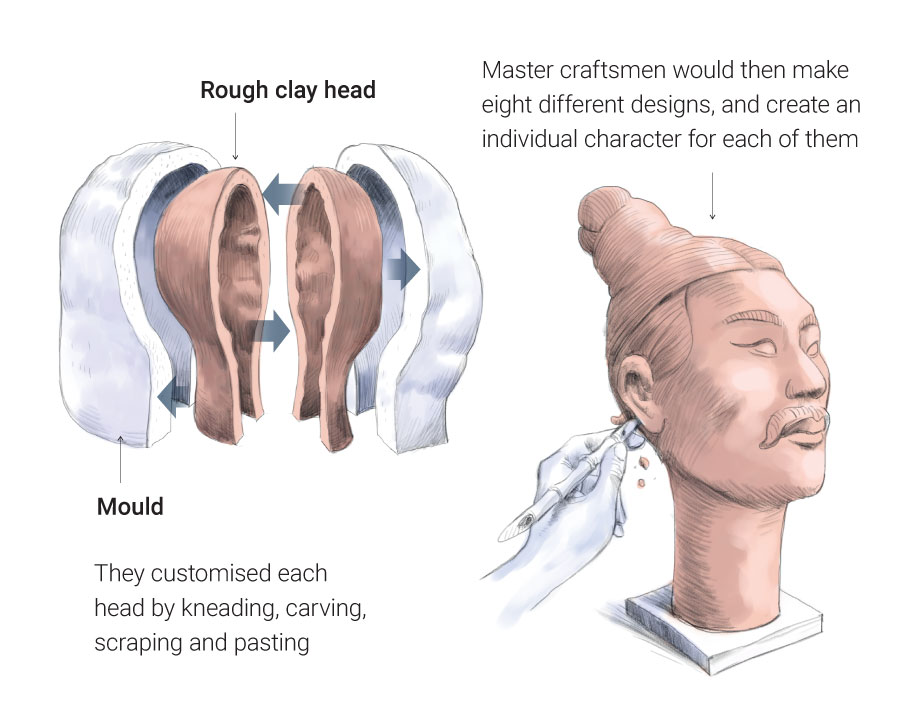

10Artisans would mould a basic head shape for mass production

Kilning process

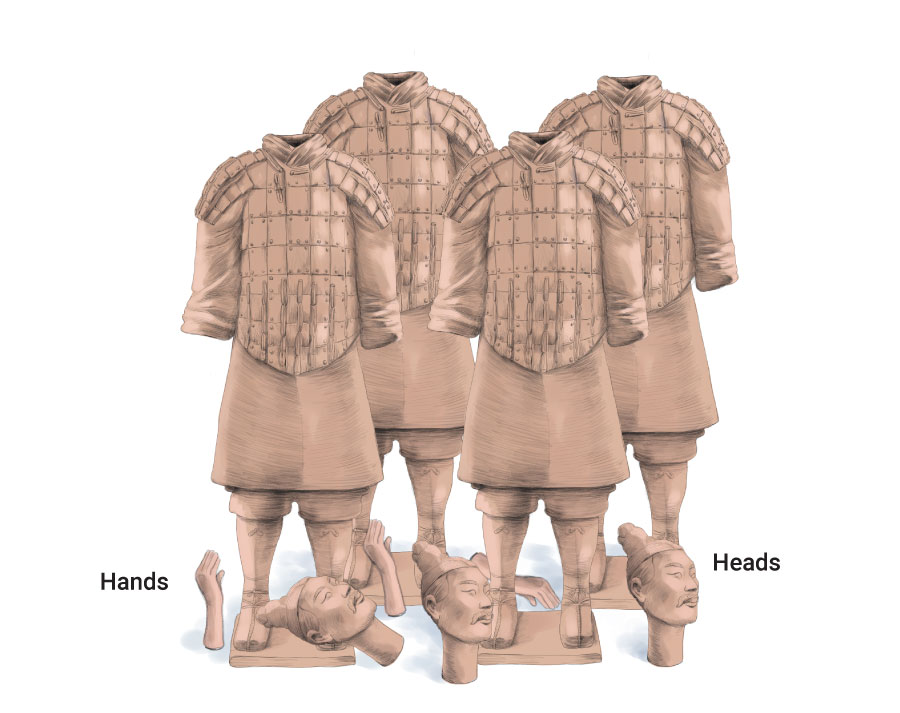

11Bodies, heads and hands were dried in the shade for at least 24 hours

Kilning process

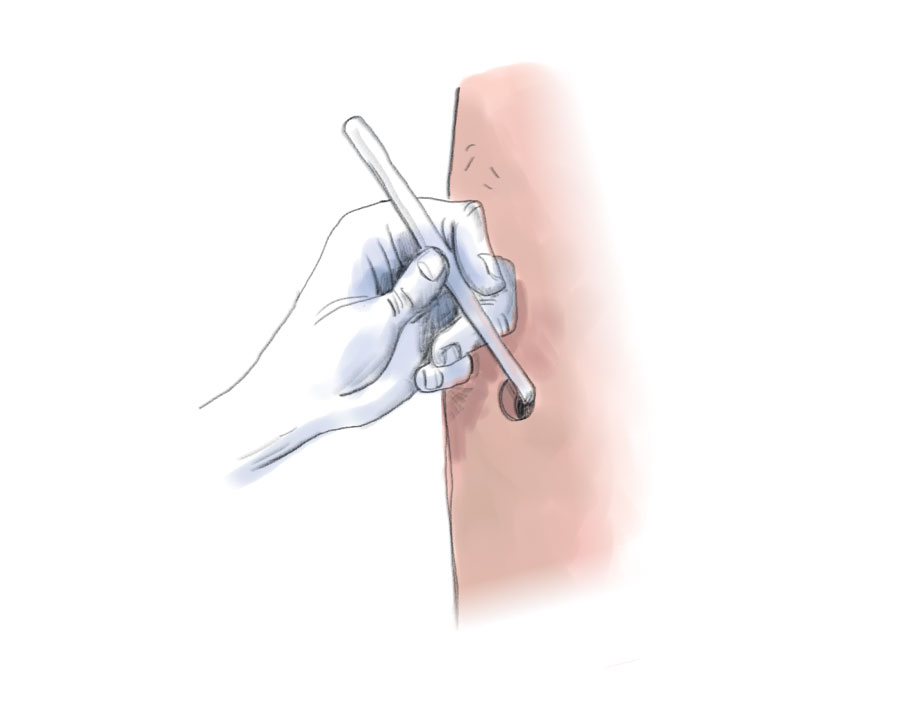

12Before baking in the kiln, or oven, one or more holes were made to allow ventilation and prevent the figure from breaking

Kilning process

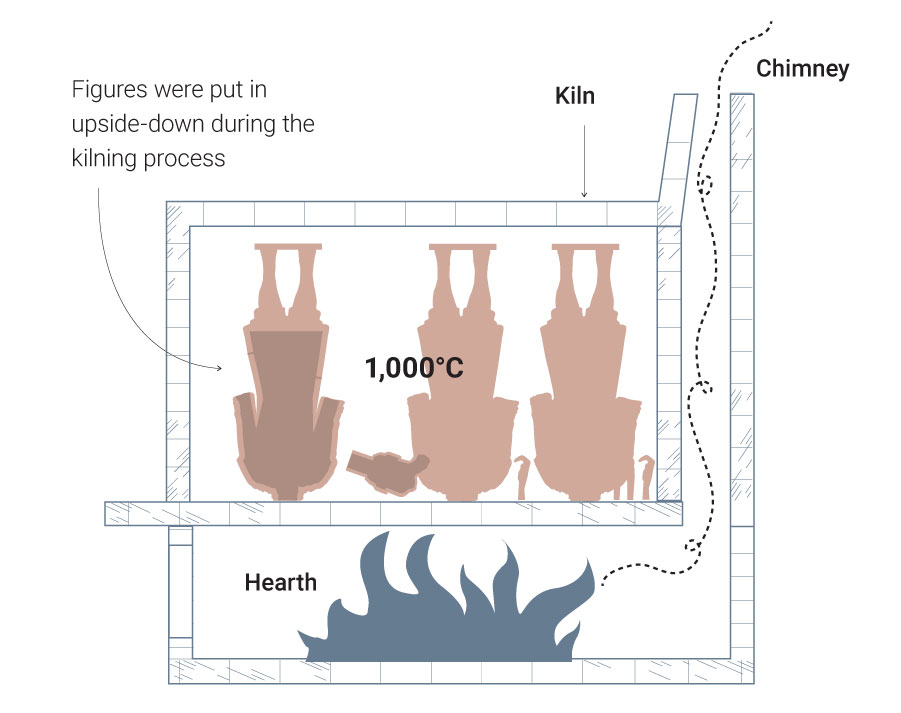

13Although we don't know much about the kiln, research shows the statues were definitely fired in a kiln

Kilning process

1412-24 hours after the process, the heads and hands would then be assembled

Colouring

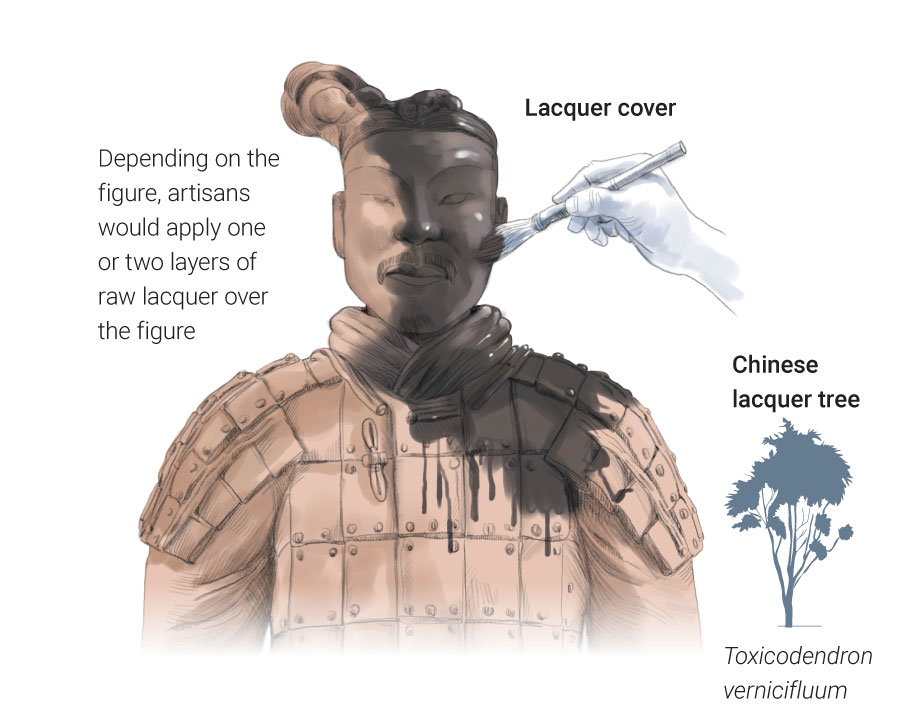

15To cover the whole figure, they would have to extract lacquer from 25 trees

Colouring

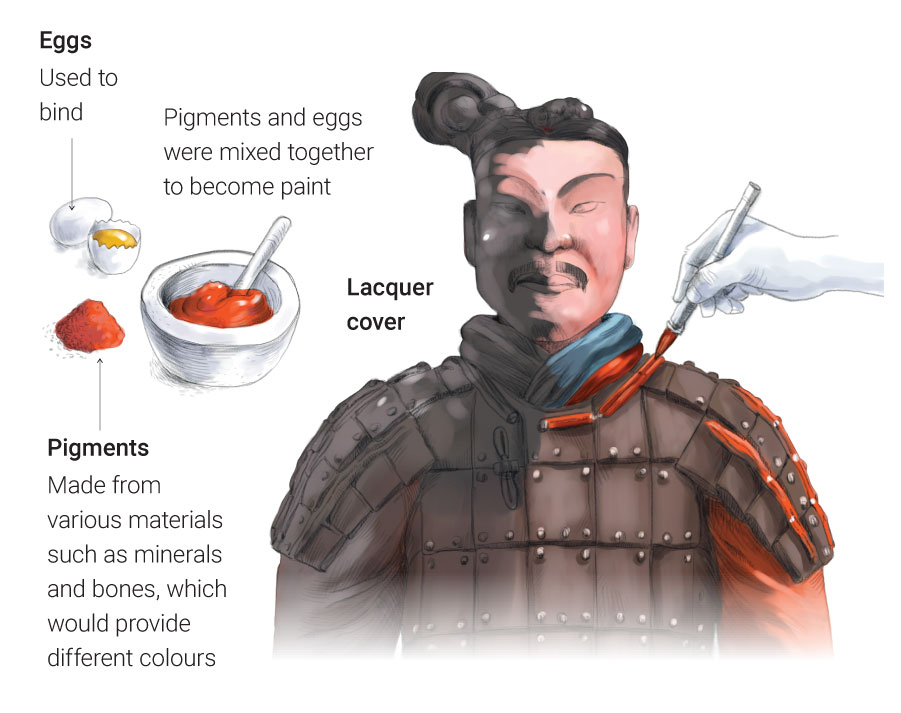

16Painters would colour over the lacquer layer, and then the terracotta warrior would be finished and ready for the mausoleum

Figure completed

17Appearance of a figure after it has been completed

-

❯

-

❮